injection moulding ppt

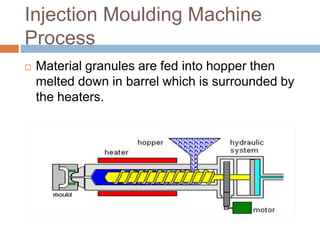

Typical packing pressure P 108 Pa for a total area of A. 60 Injection Moulding StagesCycle The sequence of events during the injection mold of a plastic part is called the injection molding cycle.

3d Printing For Molds And Dies Part 1 3dprint Com The Voice Of 3d Printing Additive Manufacturing Injection Moulding Process Plastic Moulding Injection Moulding

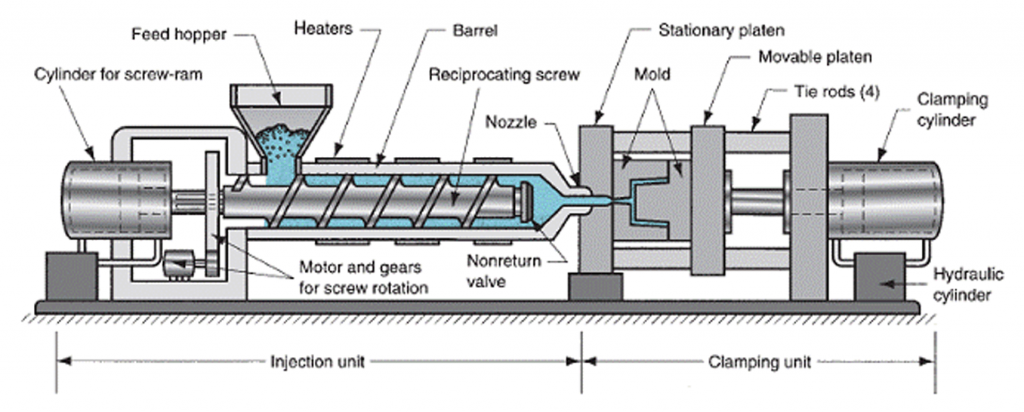

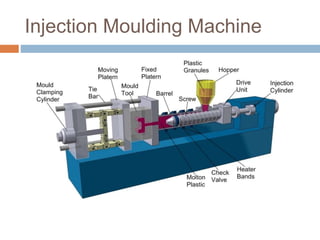

Reciprocating Screw Type Injection Moulding MC Machine components The Reciprocating Screw The feeding zone The compressing or transition zone The metering zone Screw Used in.

. Therefore showing liquidity by flow length of spiral or bar flow type mold is general for practical purposes. Evaluate the actual liquidity of the material when injection molding. Injection pressure is too high or clamping force is too weak.

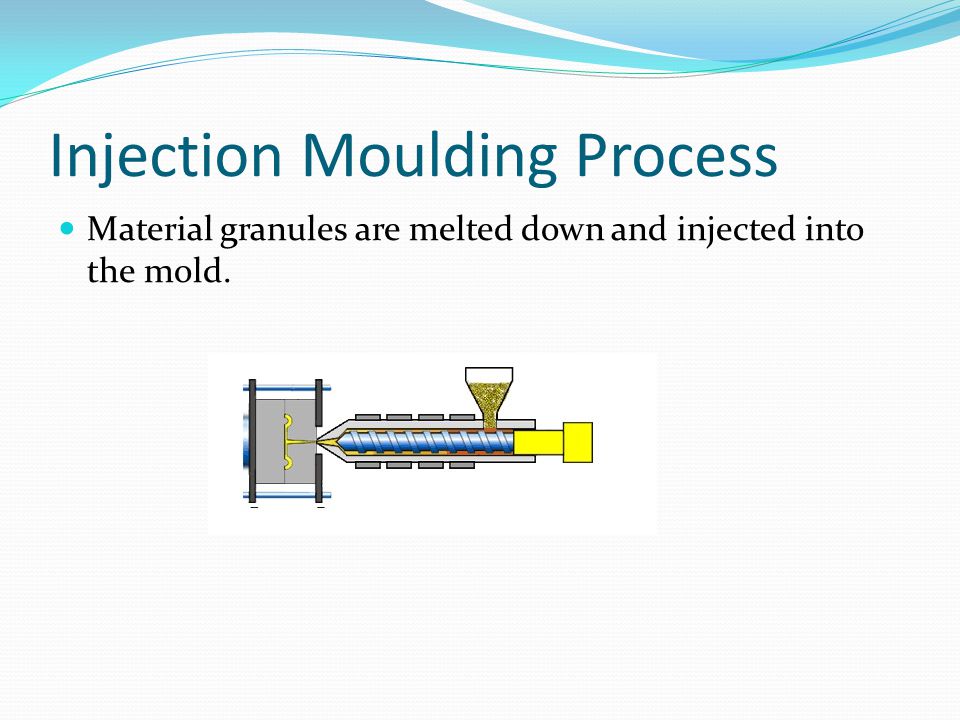

It works by injecting molten materials into a mould or mold in the United States. Close dimensional tolerances can be maintained. A plastic material usually called a resin is melted and forced into a mould via injection.

Injection moulding can be performed with a host of materials including metals glasses elastomers confections and most commonly thermoplastic and thermosetting polymers. PPT layouts consisting of injection molding - female dentist holding a dentistry background and a light gray colored foreground Amazing presentation theme having production quality control in metallurgy backdrop and a gray colored foreground Slide set consisting of an injection with a medical sign in the background. Screw continues moving forward for packing.

Screw in full forward position. Where is injection molding. Import quality Injection Moulding Ppt supplied by experienced manufacturers at Global Sources.

We use cookies to give you the best possible experience on our website. Pressure P is used to pack the mold. A thin plastic skin forms and solidifies in the mold wall.

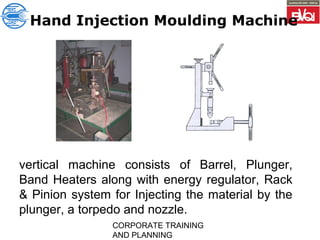

It is typically used as a mass production process to manufacture thousands of identical items. Plunger type Injection Moulding MC. Shrinkage is of order 10-1001000 for unfilled and 1-101000 for filled across the thickness 29 Where is injection molding.

Parts can be moulded with metallic and non-metallic inserts. Clamping force to hold mold closed. Ejection points Plastic must be ejected square to the mould Tapered sides Tapered sides allows the product to be removed from the mould.

Packing pressure must be maintained until the gate solidifies. Flow length will change by following factors so need to take a hold of effects that. The process is simple in principle.

Slow down the injection speed. For more details including how to. Screw moves forward for injection.

Apply well-balanced pressure to the mold to get consistent clamping force or increase the clamping force. Injection molding is a manufacturing process for producing parts by injecting material into a mould. Same items can be moulded in different materials without changing the machine or mould in some cases.

When showing liquidity flow length L is used and sometimes ratio Lt between cavity thickness t will be 6 used. Dharmendra Kumar Yadav Mtech Rubber Technology IIT Kharagpur Type of Injection Moulding Machine Hand Injection Moulding MC. A TYPICAL INJECTION MOULDING SYSTEM Basic Phases in Injection Moulding Mould Closes 1st Stage Filling 2nd Stage Packing Cooling and Plasticising Mold Opens Part Ejected.

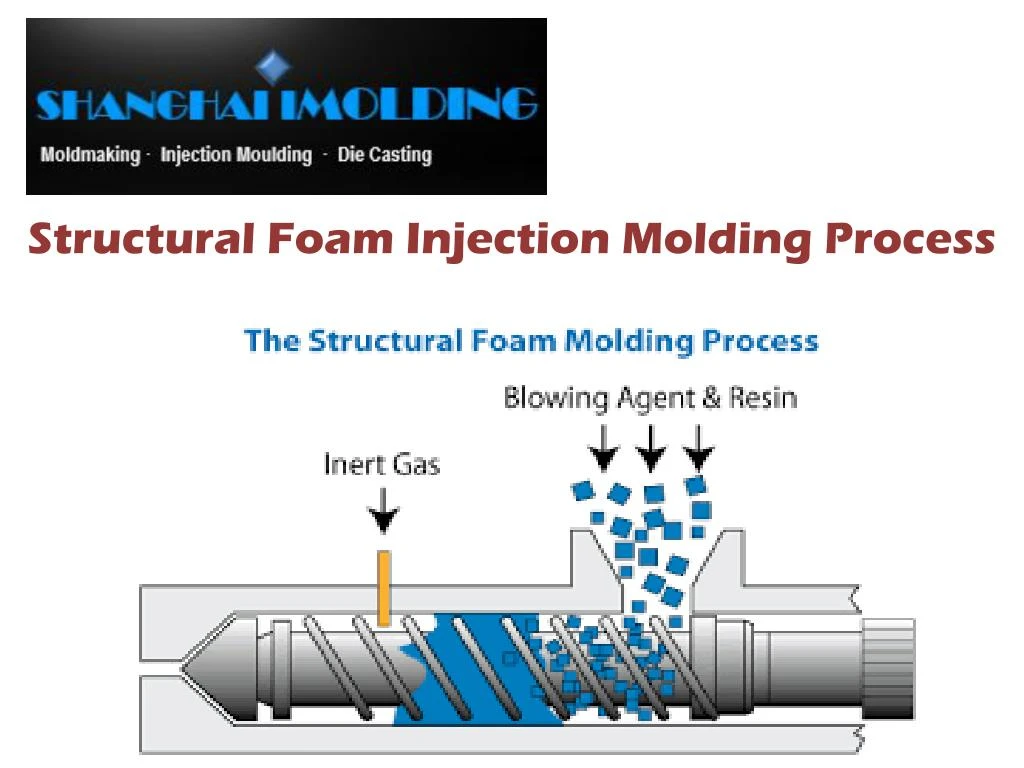

Foaming happens as the melted plastic material enters the mold cavity. Disadvantages of Injection Molding The total amount of scrap produced during injection molding will usually be higher than that for compression molding Disadvantages of Injection Molding Warpage can be a problem in injection Disadvantages of Injection Molding The filling of the parts through one or two gates produces parts that have knit lines. PPT theme having some pills with two syringes two vials and a thermometer Amazing PPT theme consisting of a number of capsules with a person being injected Colorful PPT layouts having female hands injecting fluid into small tomatoes.

Plastics are by far the most common materials that are produced using injection moulding. In the next step the screw turns feeding the. Plastic injection mould manufacturer in china - a plastic molding manufacturing company works on injection molding machine and plastic mold meltdown plastics and inject it into the mold by high injection speedonce the plastic is in the mold cavity it forms the shape of the object you desire after the plastics get cold in the mold and eject.

Injection moulding is a manufacturing process that allows for parts to be produced in large volumes. Advantages of Injection Moulding Process Minimal scrap loss result as runners gates and rejects can be reground and reused. Inserting a small amount of nitrogen or chemical blow agent into the plastic material makes the walls thicker.

Find Injection Moulding Ppt manufacturers from China. Avoiding excessive difference in thickness is most effective. Controlled by shrinkage and warping.

PowerPoint Presentation Plastic Injection Molding Nachiket Kulkarni 12082016 Introduction Various optical technologies have plastic components Injection molding can achieve mass production Producing components with machining process may be expensive Economical Plastic is an alternative to glass Limited by physical properties. F Z A PdA 2πP Z R 0 rdr πR2P General Result F PA Example. Injection moulding is the primary method for creating plastic parts components and products.

Injection Molding PACKING STAGE When the mold is full flow stops so there is no longer a pressure drop. Once the cavity is filled a holding pressure is maintained to compensate for material shrinkage. Hence polymer fillers mold geometry and processing conditions can all influence the final tolerance.

Slides consisting of detail of injection moulding tool background and a navy blue. Poor quality of the moldThe molten polymer has too low viscosity. PowerPoint Presentation Injection Moulding Injection point The point where the plastic entered the mould.

The cycle begins when the mold closes followed by the injection of the polymer into the mold cavity.

Ppt Key Benefits Of The Structural Foam Injection Molding Process Powerpoint Presentation Id 7849930

Basic Knowledge Of Injection Molding Process

Why Choose Injection Moulding Geomiq

Injection Moulding Technique Presentation

3 Basic Steps Of The Injection Molding Process Injection Moulding World Magazine

Injection Molding Process Materials Cycle Defects

Injection Molding Process Xcentric Mold Engineering

What Is The Injection Moulding Ppt Video Online Download

Injection Moulding Technique Presentation

What Is Injection Moulding How Does Injection Moulding Work

The Outline Of Injection Molding

Plastic Injection Moulding Machine Process Animation Construction And Working Setup Diagram Youtube

Comments

Post a Comment